Maximize EV range with Pre-Switch

Pre-Switch™ eliminates switching losses, enabling 10X higher switching frequencies and much higher efficiency

Disruptive

drivetrain technology

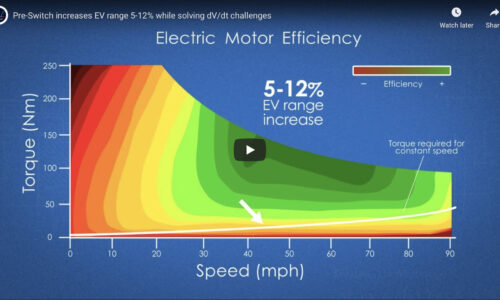

Reduce

inverter losses

Reduce

Motor Losses

Pre-Switch for E-mobility = Further Smaller Lighter Cooler

Embedded AI adapts for all loads and voltages

- Highest peak (>99.5%) and low-load inverter efficiency

- Highest discrete power density >210kW/L

- Motor-loving 100kHz switching frequency

- Lossless di/dt & dV/dt filter improves reliability

- Minimized motor bearing current reduces failures

- Predictive maintenance

- Dramatically reduced EMI

- Operates outside human audible range

Resources

Initial Prototype: power up and first AI learning

Pre-Switch increases EV range 5-12%

Pre-Switch Technology White Paper

Products

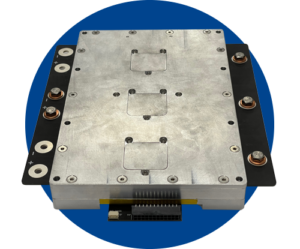

CleanWave EV Inverter

Evaluation System

This is an evaluation system for CleanWave, a fully-functional 200kW inverter with integrated motor control, CAN bus interface, DC link capacitors and safety features. It achieves a class-leading peak efficiency of 99.5% at 100kHz and delivers a power density of 210kW/L. Pre-Switch also offers a customization service enabling CleanWave to be used as a stand-alone inverter.

CleanWave Inverter

Platform

A family of inverters with the class-leading efficiency and power density performance of CleanWave. Available in 100kW, 150kW, 200kW, 250kW, 300kW, 350kW and 400kW power ratings.

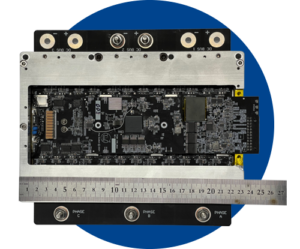

Pre-Flex SoC

Pre-Flex ICs contain all the AI algorithms necessary for soft switching across all operating voltages, load conditions and temperatures. The SoC also enables motor control for permanent magnet motors, and includes embedded diagnostics with digital scope and customer code API library.

CleanWave Inverter Licence

All the software necessary to run the

Pre-Flex SoC. Does not include

source code.

Register for more information

"*" indicates required fields

Join our mailing List

I would like to receive updates from Pre-Switch. I understand I can unsubscribe at any time.

Company