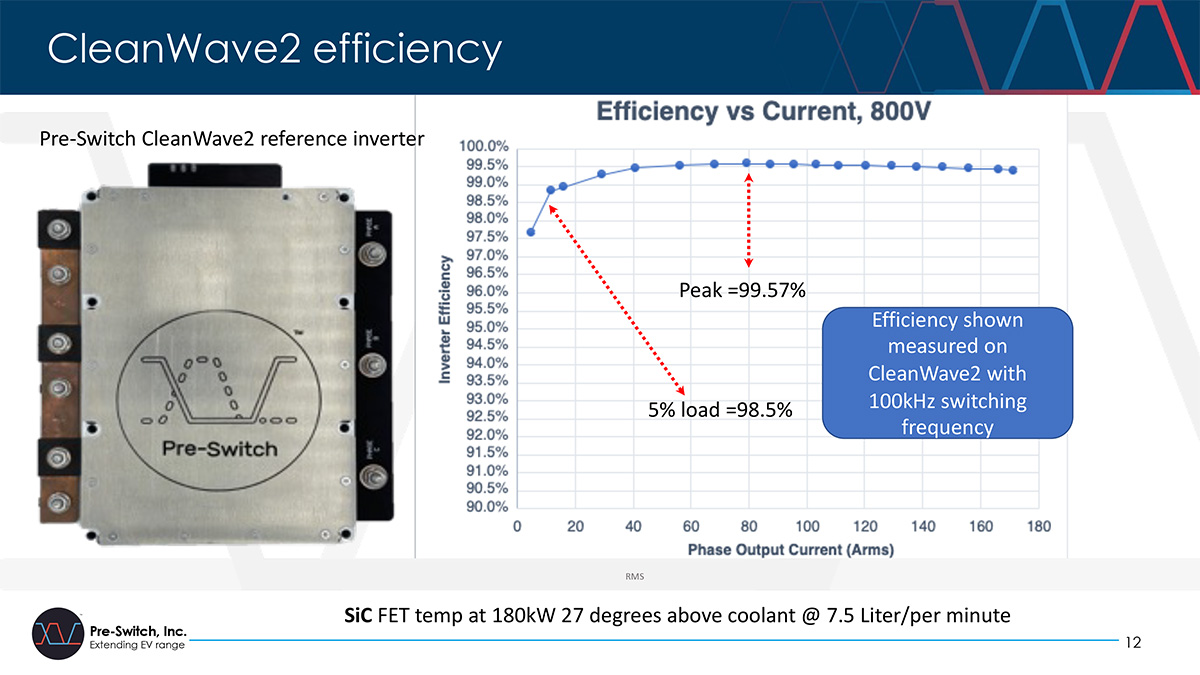

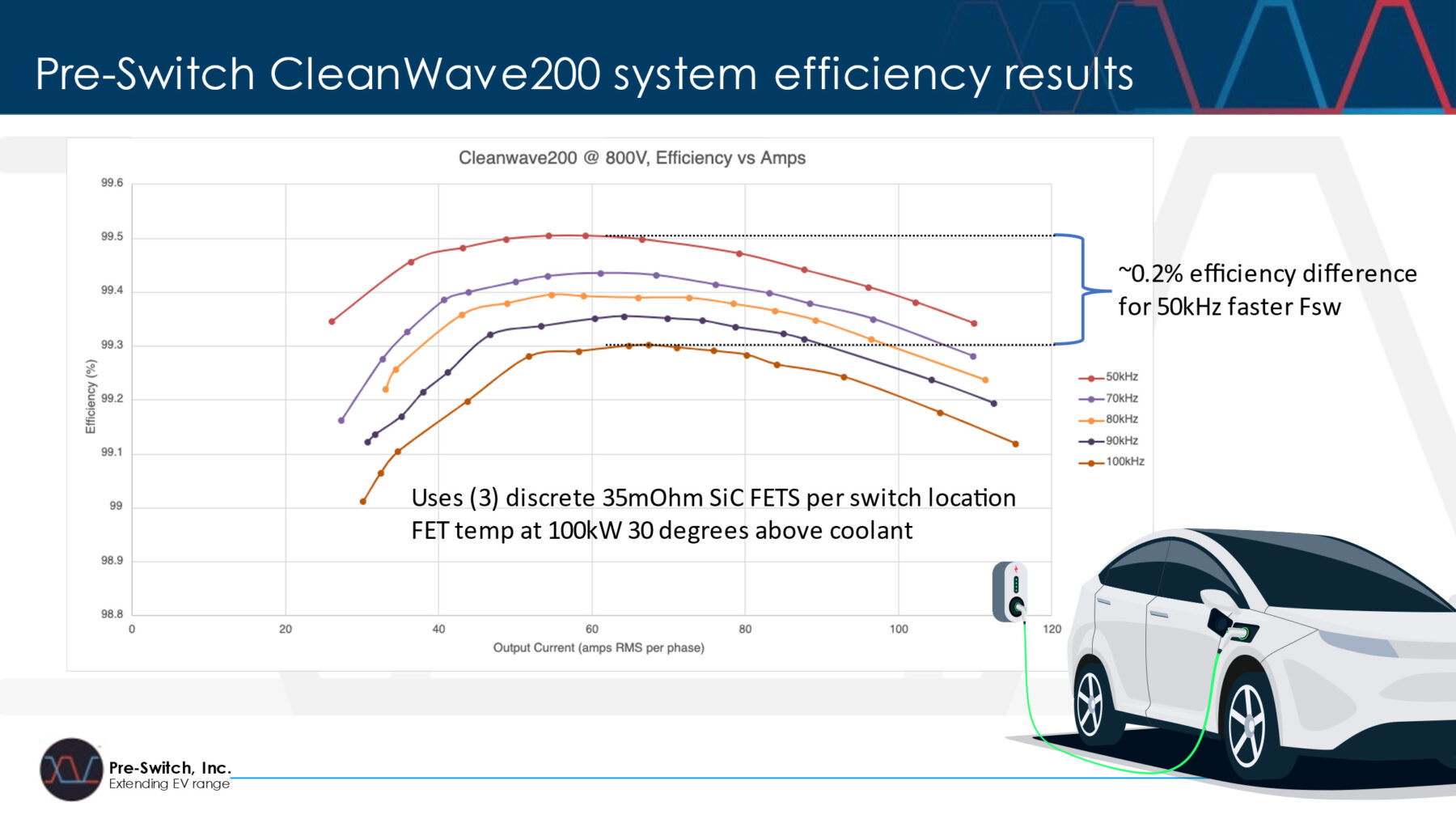

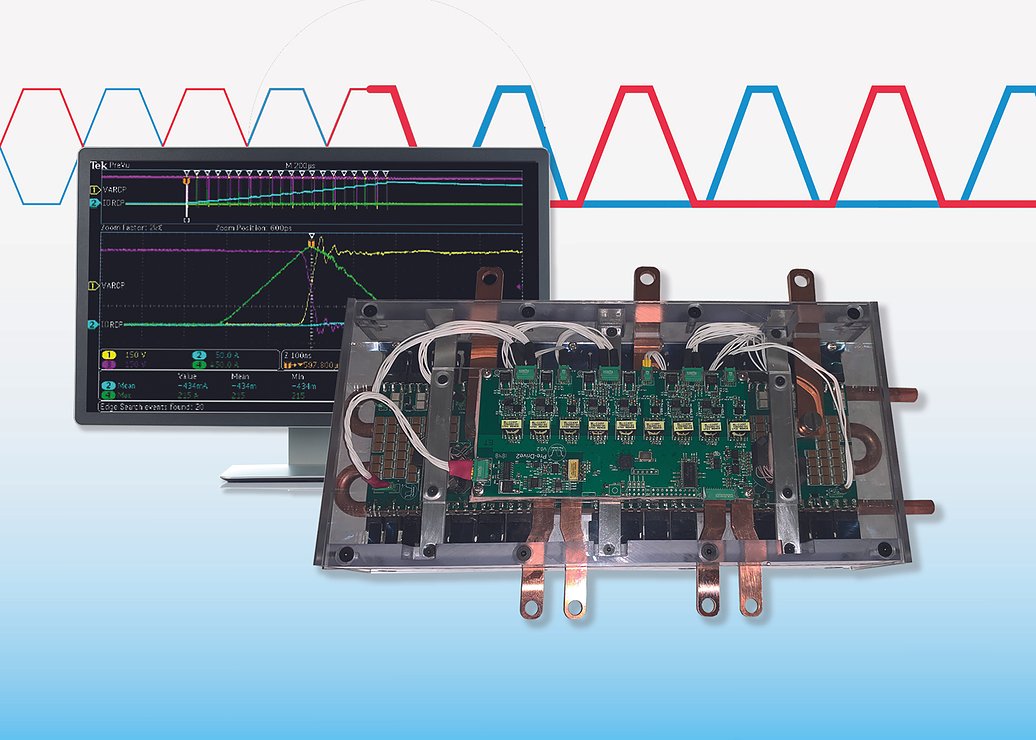

The Pre-Switch soft-switching solution effectively eliminates switching losses for wide bandgap (WBG silicon carbide + gallium nitride) transistors, and reduces IGBT switching losses by approximately 65-80%, resulting in increased efficiency. Specifically, efficiency is improved in the low operating points for inverters where switching losses dominate total losses. With Pre-Switch, the result is an inverter with higher peak efficiency, higher average efficiency and higher low load efficiency.

The elimination of switching losses also reduces cost by allowing designers to pass more current through a transistor with the same transistor loss budget. This is possible because the transistor is no longer dissipating switching losses as wella as conduction losses. There is also a second order improvement in transistor conduction losses because the transistors are operating at lower temperatures. Both factors combine to reduce cost and size of an inverter.

The elimination of switching losses means that inverter switching speeds – which today are limited to slow (10-15 kHz) frequencies in order to maintain efficiency – can be run 5-10X faster (50-100kHz) with the same or higher efficiency. Pre-Switch’s higher switching frequencies have profound inverter and motor benefits. They include: a high quality sine wave sent to the motor which improves motor efficiency; a reduction in the DC link capacitor size and cost by up to 90%; the elimination of audible noise that can be heard by human ears; and reduced common mode noise in the motor between the rotor and stator which is known to ruin motor bearings.

A Pre-Switch inverter with a 10X faster switching frequency produces a low distortion sine wave output – a ‘clean wave’. This improves motor efficiency and adds range – especially where EVs are driven at low rpm and low torque conditions. Hence, we have adopted the name ‘CleanWave™’ for our inverter reference design.

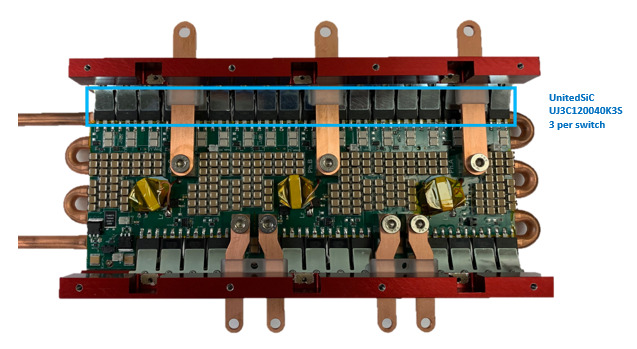

The Pre-Switch technology enables designers to build a lighter and lower cost inverter, as discrete transistors can be used instead of heavy and expensive power modules. Until Pre-Switch, discrete transistors have been of only limited use in high current applications due to the challenge of current sharing, EMI mitigation and assembly costs. With Pre-Switch, transistors have no current or voltage across them when they turn on and turn off. The result is that simple transistor paralleling can be used and a dramatic reduction in EMI achieved. Both these factors help reduce inverter cost, size and weight.

Lastly, Pre-Switch technology virtually eliminates EMI because each transistor is turned on and off with no voltage or current present.