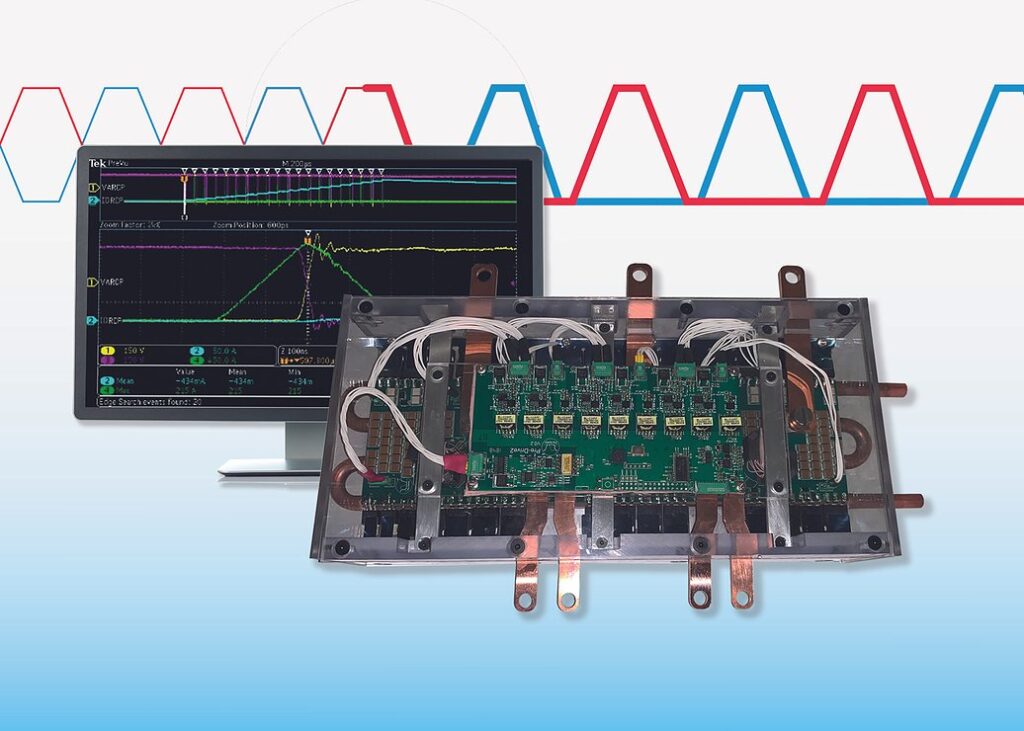

Bruce Renouard – March 11 2020, Campbell, Ca., USA: Pre-Switch, Inc., a Silicon Valley start-up that has developed the world’s-first AI DC/AC, AC/DC soft-switching controller delivering efficiency and performance benefits to a wide range of applications including EVs and renewables, has released first data from its Cleanwave 200kW inverter reference. Double pulse test data demonstrates that the Pre-Switch soft-switching platform – comprising the Pre-Drive™3 controller board powered by the Pre-Flex™ FPGA, and RPG gate driver board – reduces total system switching losses by 90% or more.

Pre-Switch is enabling customers to build systems with switching frequencies 4X-5X faster than their hard-switched IGBT systems and 35X faster than their hard-switched SiC and GaN systems: this is achieved with half the transistor count. In the case of a SiC-based EV inverter, increasing the Fsw from the ubiquitous 10kHz up to 100kHz or 300kHz creates a near perfect sine wave without any output filter. The result is elimination of unnecessary motor iron losses and an increased motor efficiency at low torque and low RPM. Higher switching frequencies also enable higher RPM motors that are lighter and lower cost.

Previously, soft-switching has never been successfully-implemented for DC/AC systems with varying input voltage, temperature and load conditions. However, Pre-Switch has overcome the challenges by using Artificial Intelligence (AI) to constantly-adjust the relative timing of elements within the switching system required to force a resonance to offset the current and voltage wave forms – thereby minimizing switching losses.

Comments Pre-Switch CEO, Bruce T. Renouard: “Our CleanWave200 evaluation system allows customers to assess the cycle-by-cycle adaption of Pre-Switch’s AI-based soft-switching technology and explore the benefits of higher switching frequencies in their application. CleanWave200 is the power block of an inverter with a PWM interface. The system bi-directionally converts 800VDC to three phase AC at power up to 200kVA with a Fsw of 100kHz and 99% efficiency.”

The Cleanwave200 evaluation system, reference design and design files can be ordered from Pre-Switch.

Pre-Switch: Further, Faster, Lighter, Cheaper – Cooler