Over 99% efficient at 100kHz using 3 5mΩ MOSFETs.

Brings significant benefits to EV and renewables.

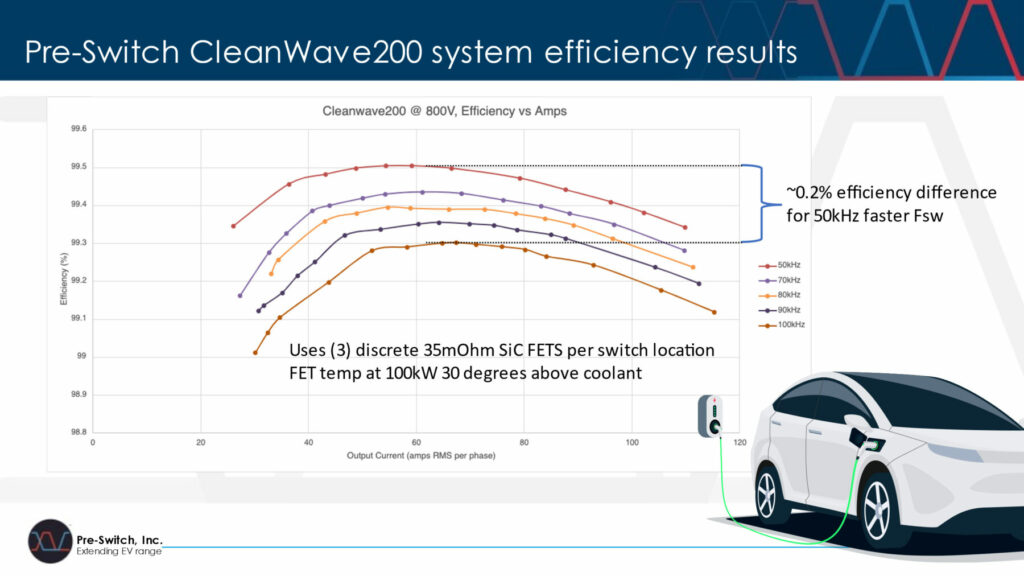

April 20 2021, Campbell, Ca., USA: Pre-Switch, Inc., a Silicon Valley start-up that has developed the world’s-first AI-based DC/AC, AC/DC soft-switching controller, has published performance data that shows that its 200kW (space vector modulated) CleanWave200 evaluation inverter exceeds 99.3% at 100kHz using only three discrete, low cost 35 mΩ SiC MOSFETs per switch location. This is expected to revolutionize EV and renewable energy designs.

Comments Bruce Renouard, Pre-Switch CEO: “We are shipping the CleanWave200 evaluation systems to initial customers around the world, and the efficiency data we are making public today more than justifies our design goals. Customers could use the Pre-Switch technology with even better MOSFETs and expect to get incremental performance gains, but there is no other approach that even comes close to 99.3% efficiency at 100kHz with such few, low cost SIC MOSFETs.”

The Pre-Switch AI enables users to migrate from lossy, expensive hard-switching implementations to high efficiency, soft-switching designs with a 10X higher switching frequency which produces an almost pure sine wave output. The Pre-Switch controller analyzes multiple inputs on a cycle-by-cycle basis, making adjustments in real time to small, forced-resonant transistors enabling perfect soft-switching in harsh changing environments. Variations in system temperature, device degradation, changing input voltages and abrupt current swings are all accounted for and optimized within the Pre-Switch AI algorithm.

The published data plots system efficiency for 50-100 kHz switching speeds, input voltages, power output and current output, enabling system designers to compare the Pre-Switch results to their own requirements. Adds Renouard: “Switching losses using our Pre-Switch technology are effectively zero. If we put that into perspective, an EV with Pre-Switch technology improves inverter efficiencies, producing a pure sine wave output that dramatically improves motor efficiency at low torques where people drive. This will result in an increase its range by up to 12%.”

The Cleanwave200 evaluation system, reference design and design files can be ordered from Pre-Switch.

Pre-Switch: Further, Faster, Lighter, Cheaper – Cooler